Prolonging Oil

Healthy Oil – No Problem

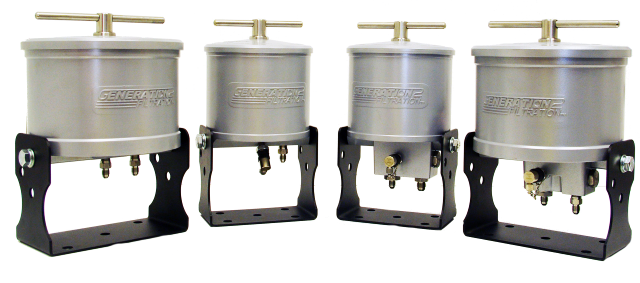

Low pressure applications can be found in a varitey of working environments, but all are prone to external and internal contamination. With G2F’s abiltiy to remove water at 99.97% from oil, the element dramatically decreases the formation of acids, diminishing the accelerated depletion of additives and corressive action within the component. On a diesel engine application, this reduction in acid formation keeps the additive package in a healthy state for much longer periods of time, keeping the Total Base Number (TBN) at a high level. By removing ultra-fine particles down to 1 micron, there is significantly less of a burden placed on the additives with less dirt to suspend, dramatically reducing mechanical wear while safely extending the oil change interval in any low pressure application.

Contaminated Oil

Contaminated Oil

Contaminated oil increases acid formation, particle build-up, varnish deposits, sludge deposits, acid pitting, corrosion, increased mechanical wear, accelerated viscosity breakdown, overheating, water contamination, poor oil circulation, oxidation and rapid additive depletion. G2F safeguards you against these problems.

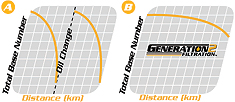

Acid Formation – How it affects TBN levels in diesel engine oil

Typical Filter (A) – The need for constant neutralization of acids formed in the engine is the major factor for TBN breakdown.

Typical Filter (A) – The need for constant neutralization of acids formed in the engine is the major factor for TBN breakdown.

With Generation 2™ (B) – Generation 2’s ability to constantly remove water creates a virtually acid free engine significantly reducing the breakdown of the additives, minimizing corrosive action, and dramatically reducing the need to change the oil.

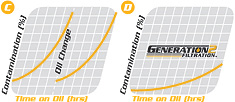

Particle Build-up

Typical Filter (C) – The constant build-up of fine particles held in suspension by the additives creates the need for regular oil changes.

Typical Filter (C) – The constant build-up of fine particles held in suspension by the additives creates the need for regular oil changes.

With Generation 2™ (D) – The constant cleaning action prevents any particle build-up and creates a much cleaner engine, dramatically reducing oil changes and mechanical wear.