A Proactive Approach to Maintenance

A Proactive Approach to Maintenance

The G2F approach to maintenance replaces the ‘failure reactive’ philosophy with ‘failure proactive’ by implementing corrective measures to avoid problems you will eventually encounter. G2F is a low cost ‘Proactive’ maintenance asset management tool. It lowers long-term maintenances costs, while providing short-term savings on oil, standard filters, downtime, and waste oil. This offers a relatively quick return on the capital investment.

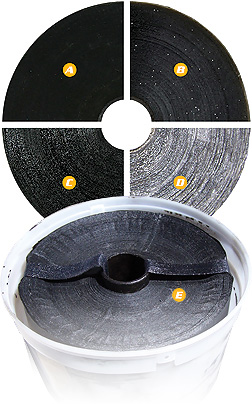

Some common engine problems can help be identified by the condition of the G2F element.

Some common engine problems can help be identified by the condition of the G2F element.

Normal Element (A) – Changed at proper interval, element removed high concentrations of soot/carbon, indicating normal engine wear.

Metal Dust Particles Present (B) – Indicating engine overload. Wear is taking place in metal component. Investigate source immediately.

Soot/Carbon Overload (C) – Higher than normal levels accumulated indicating possible overheating, engine overload, coolant system malfunction, or due to extreme element extension intervals.

Fuel Dilution (D) – Element will become dry and turn grey in colour, indicating fuel is present in the oil.

Coolant Leak (E) – Element is spongy and shrunken indicating water is present in the oil.